contacts:Mr. Zhang

Mobile:086 13929224225

Tel:+86-769-85625718

Add:Building A1, Tingfeng Science and Technology Park, Nanqu Industrial Zone, Dalingshan Town, Dongguan City, Guangdong Province

What is the application scope of plastic transparent adhesive printing?

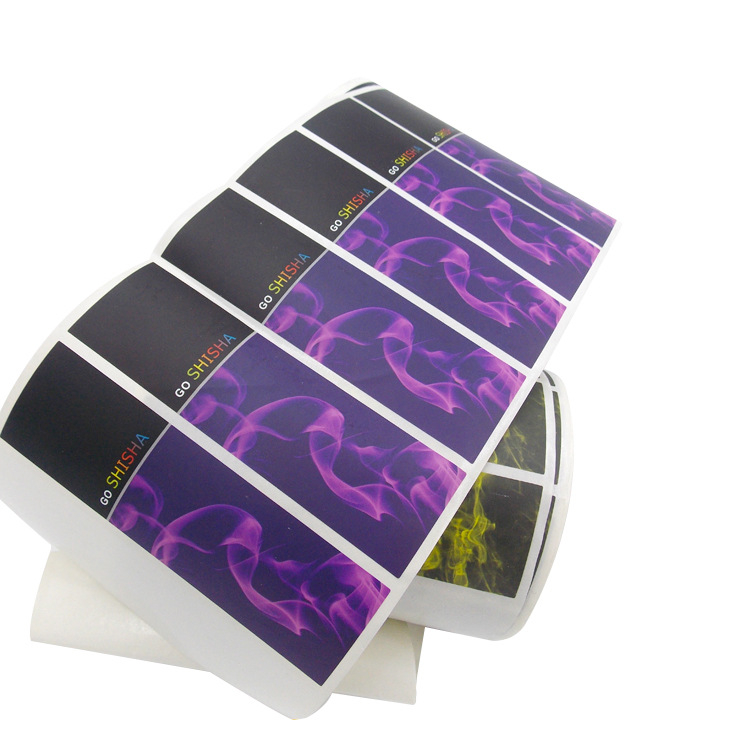

The appearance of plastic parts in electronic products is printed with transparent adhesive. Electronic products, especially digital cameras, MP4 players, televisions, and computers, have high requirements for appearance. After the development of plastic transparent adhesive printing, it has brought convenience to the decoration of electronic products. Transparent adhesive printing of plastic logos. In recent years, plastic signs and decorative parts used for transparent adhesive printing of graphic characters after plastic molding have developed rapidly. Transparent adhesive printing on dashboard. Transparent adhesive printing of colored polyester logo. The principle of transparent adhesive printing is that a part of the mesh of the transparent adhesive printing plate can be blocked by ink, while the rest of the components are blocked. If the mesh cannot pass through, apply a layer of photosensitive material on the screen and use the difference between its photosensitivity and solubility to wash away the unwanted parts after photosensitivity, thereby controlling where the ink can pass and where it cannot pass. Transparent adhesive printing of plastic parts is one of the secondary processing (or reprocessing) of plastic products.

What are transparent adhesive materials and processes?

Thin film covering process: refers to the application of transparent plastic film onto the surface of printed materials through hot pressing to protect and increase gloss.

Die cutting process: Printed or other paper products can be made into die-cutting blades based on pre designed graphics, so that the shape of printed products is no longer limited to right angles and straight edges. The default die-cutting process for rotating machines.

Put a large piece of paper together: choose the working time after assembling the large board. The size is the size of a single small finished product. The quantity refers to the number of large boards assembled, and the shape is die cut. After assembling the large board, enter the number of connections between the long and short sides in the text box (how many long sides were assembled and how many short sides were assembled to maintain the balance of the length to width ratio of the large board).

White printing process: The normal white printing process is CMYK four-color printing. If you want to print white patterns on transparent adhesives and materials, and use their own background colors, you need white ink.

Bronze plating process: Heat the prepared hot stamping plate, peel off the metal foil from the original substrate layer at high temperature, and transfer it to the position that requires hot stamping.

Oil coating process: The oil coating process is to apply a layer of bright oil on the surface of the printed material to achieve a bright surface and a slight waterproof effect. Transparent adhesive printing is an ancient and widely used printing method. According to the different materials of the printing object, it can be divided into: fabric printing, plastic printing, metal printing, ceramic printing, glass printing, transparent adhesive printing, advertising board transparent adhesive printing, stainless steel product transparent adhesive printing, transparent adhesive printing, and paint transparent non drying adhesive printing.

administrators

There are currently no comments on this content